Main Product: granite,marble

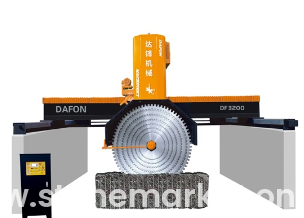

Integrated Infrared Bridge Cutting Machine For Marble And Granite

FOB Price :

15000 - 18000

$

Others

Usage: Granite,Marble,Limestone,Artificial Stone,Basalt,Quartzite

After Sale

Warranty:12 Months

Install and Guarantee: Remote Guidance Installation,

Maintenance: Online software upgrade

Trade Terms

Port:Xiamen Port, Shekou Port, Ningbo Port,,

Shipment Terms:FOB,CFR,CIF,EXW

Payment:T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow

You may also like

Integrated Infrared Bridge Cutting Machine For Marble And Granite

Machinery Function Features

Machinery Function Features

Infrared automatic bridge stone cutting machine is an ideal equipment for cutting and processing products of this type. Before cutting, infrared knife setting is used. After setting operating parameters, the cutting process is automated and programmed. One-piece bridge type stone cutting machine is one of many types of infrared automatic bridge type stone cutting machine.

Features

1. The PLC control system is adopted, and the operating parameters (including cutting size specifications, moving speed, etc.) are input through the man-machine dialogue interface, and the cutting process is automated and programmed.

2. Use infrared tool setting to confirm the position of the workpiece and arrange the processed products

3. The whole machine is a one-piece frame, which is suitable for foundations of various natures, and it is more convenient to install and install.

4. The hydraulic control table The table panel can be turned vertically 85°.

5. The diamond disc saw blade with a maximum size not exceeding ¢400 can be hung

6. The lifting and lowering of the machine head is driven by hydraulic pressure, and the machine head can be turned 45° around the Z axis, so that the cutting tool can be rotated 45°.

7. For horizontal and vertical slicing, the magnetic grid is used to detect the length of the slicing

Technical Data

| Parameter | Unit | DFQ-F350 |

|---|---|---|

| Machine height | 4 | 3000 |

Components

Consumables

You may also like

China

China

Danny Pan

Danny Pan